Optimal Firewood Moisture Content for Efficient Combustion

Why Moisture Content Matters

Firewood moisture content is a fundamental factor in combustion efficiency, heat output, and stove performance. While it is commonly stated that only dry firewood should be used, it is the specific range of moisture that determines how well firewood performs in heating applications.

Freshly cut wood can contain natural moisture levels of 60% or more. To an untrained eye, wet and dry logs may look similar, but their energy value is significantly different. One kilogram of wet firewood can contain more water than usable wood material.

During combustion, excess moisture absorbs a large portion of heat as it evaporates. This results in reduced heat output, unstable flames, and incomplete combustion. Incomplete combustion increases emissions of unburned particulates that exit through the flue system and contributes to stove and chimney fouling.

Learn more about firewood products and their specifications here.

Recommended Moisture Range for Firewood

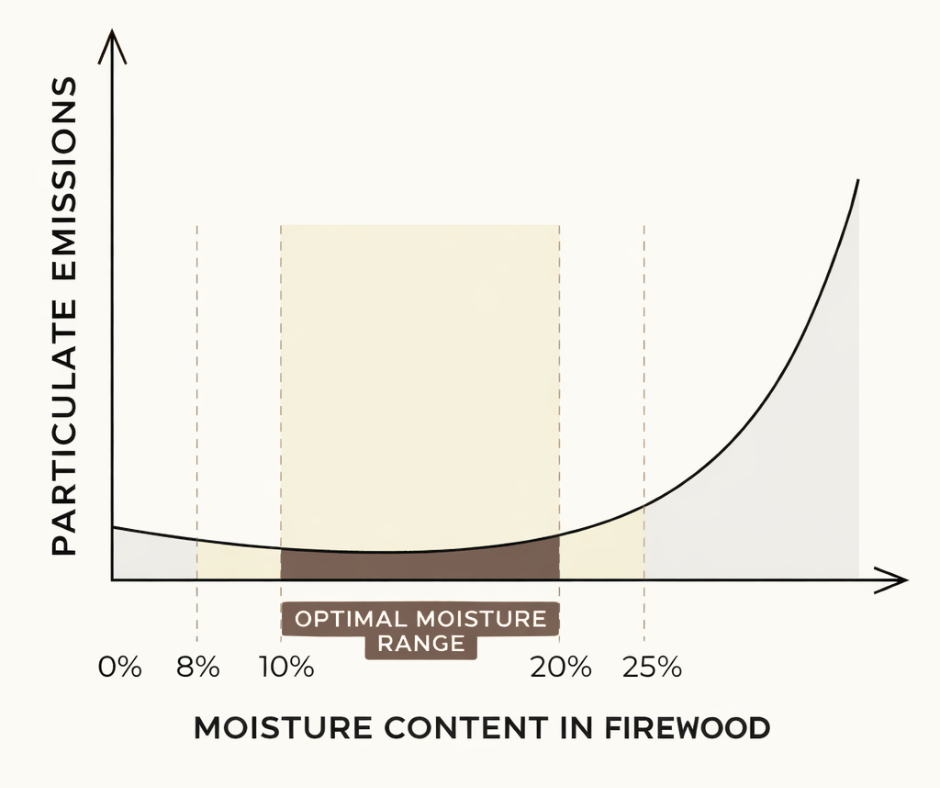

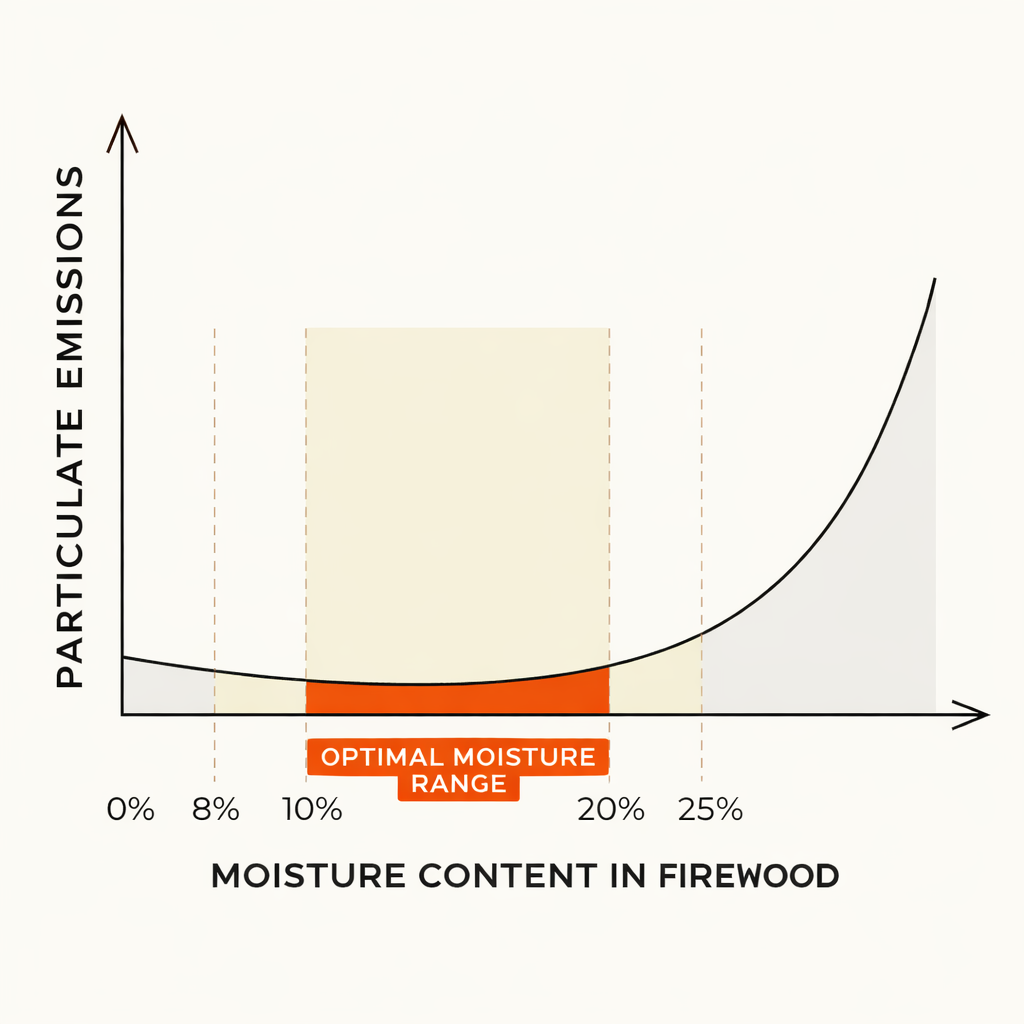

Contrary to the assumption that drier is always better, firewood with zero percent moisture is not optimal for modern stoves and fireplaces.

Industry recommendations generally specify firewood with a moisture content between 10% and 20%. Within this range, combustion is stable and predictable. A small amount of moisture helps regulate the burn rate and heat release, leading to consistent performance.

If firewood is excessively dry, it burns too rapidly. This can draw excess air into the combustion chamber, cool the flue system, and lead to increased particulate emissions due to unstable flame behavior.

For answers to common questions about firewood use and performance, see the FAQs section.

Industrial Kiln Drying vs Air Drying

Traditional air drying relies on natural exposure and storage time. While it can lower moisture levels, it often stabilizes around 20% to 25% moisture, depending on conditions.

To achieve a consistently lower and uniform moisture level in firewood, industrial kiln drying is used. Controlled drying environments make it possible to reduce moisture precisely to the 10% to 20% range, supporting reliable combustion and performance across batches and wood types.

You can explore company initiatives and production technology in the Projects section.

Consistent Quality and Performance

Kiln dried firewood is widely recognized as a preferred fuel option for modern heating systems. It supports efficient heat transfer, reduces operational issues linked to moisture, and aligns with performance expectations from stove manufacturers.

At VLI Timber, kiln drying is part of the quality control process. This ensures firewood meets consistent technical and performance standards expected by professional partners and heating system manufacturers.

For more information about VLI Timber, its mission, capabilities, and certifications, visit:

→ About VLI Timber

→ Certificates

→ Environmental responsibility